At TIESA, we understand the importance of dependable temperature and humidity control systems. Every business that relies on refrigerated or controlled environments must ensure its equipment is fully functional and stable at all times. When systems run well, they help protect valuable inventory, support productivity, and maintain smooth operations. That’s why our refrigeration service solutions are built around reliability, efficiency, and long-term performance.

We provide trusted support that helps maintain system health, avoid failures, and reduce operating costs. Whether you need repairs, emergency assistance, equipment replacement, or system upgrades, our skilled team is prepared to deliver service with careful attention and technical expertise. TIESA is committed to safeguarding your operations with proactive problem-solving and dependable care. When conditions must be stable, you can count on us.

Understanding that every site has unique requirements, we tailor our refrigeration services to suit your system type, operational workflow, and environmental standards. Our team integrates focus, discipline, continuous learning, and rigorous quality control into each job. We continually refine our processes to ensure equipment remains resilient, allowing businesses to operate confidently within strict temperature and compliance standards. With safety and reliability at the forefront, TIESA stands as your partner in creating dependable, stable environments that support ongoing success.

Unexpected issues can slow down or even halt operations. When equipment fails, immediate attention becomes essential to avoid costly downtime, wasted product, and unexpected risk. TIESA provides fast, accurate refrigeration service repairs delivered by experienced technicians trained to handle temperature and humidity control systems of varying sizes and complexity.

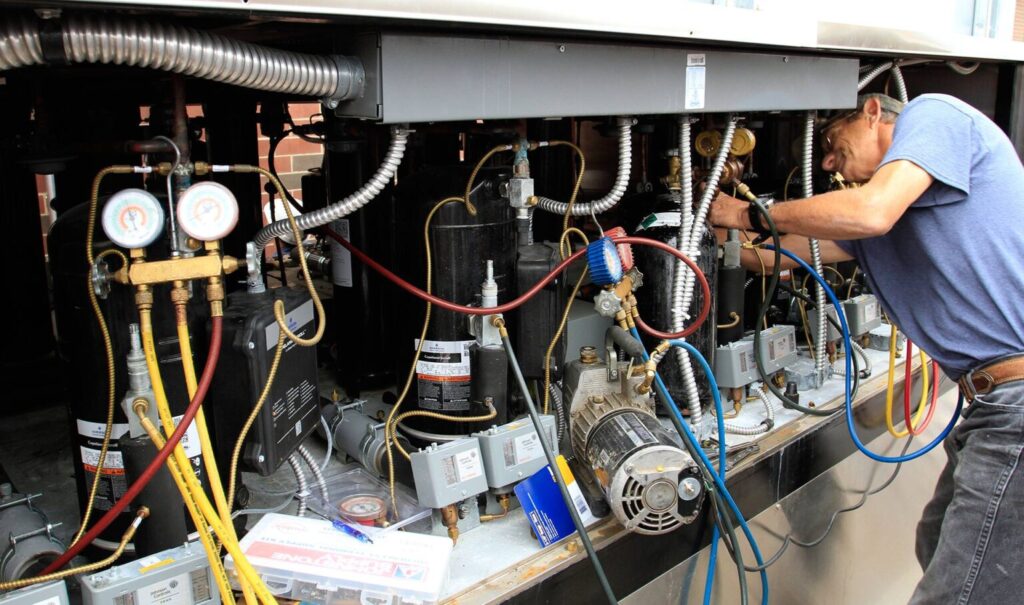

Each repair begins with a detailed diagnostic process to identify the true source of the problem before corrective work begins. This ensures repairs are not only swift but dependable. Our technicians address issues such as unstable cooling, temperature fluctuations, erratic humidity readings, reduced efficiency, airflow inconsistencies, and compressor failures.

Throughout the repair process, we communicate clearly—explaining the cause of the issue, necessary repairs, and steps to prevent recurrence. Our objective is not only to restore function but also to strengthen long-term system performance. This proactive approach reduces future breakdowns, lowers energy usage, and supports precise temperature control.

For facilities where quality control and regulatory compliance are essential, you can trust our repair services to maintain operational continuity. TIESA’s expertise helps you avoid disruptions and ensures your environment remains stable and predictable. We focus on accuracy, preventative insight, and long-term system reliability.

Temperature-sensitive environments often operate continuously, meaning system failures can happen outside standard business hours. When emergencies arise, immediate response is crucial to protect product quality and avoid costly losses. TIESA provides 24/7 emergency refrigeration service designed to respond quickly to urgent issues—day or night.

Each repair begins with a detailed diagnostic process to identify the true source of the problem before corrective work begins. This ensures repairs are not only swift but dependable. Our technicians address issues such as unstable cooling, temperature fluctuations, erratic humidity readings, reduced efficiency, airflow inconsistencies, and compressor failures.

Throughout the repair process, we communicate clearly—explaining the cause of the issue, necessary repairs, and steps to prevent recurrence. Our objective is not only to restore function but also to strengthen long-term system performance. This proactive approach reduces future breakdowns, lowers energy usage, and supports precise temperature control.

For facilities where quality control and regulatory compliance are essential, you can trust our repair services to maintain operational continuity. TIESA’s expertise helps you avoid disruptions and ensures your environment remains stable and predictable. We focus on accuracy, preventative insight, and long-term system reliability.

Over time, cooling and control systems begin to show signs of wear. Components age, efficiency decreases, and maintenance costs may rise. When repeated repairs no longer provide lasting reliability, replacement becomes the smarter long-term solution. TIESA provides equipment replacement services to help your refrigeration systems stay dependable and productive.

Our team begins by evaluating your existing setup, observing its operational performance, history of failures, and energy usage. We then recommend replacement options best suited to your business needs. The goal is to provide equipment that integrates smoothly with your facility while delivering improved stability, reliability, and performance.

Newer equipment often offers better precision, stronger cooling consistency, and more efficient humidity regulation, which helps reduce operating costs. With proper planning and execution, replacement can greatly improve temperature stability, reduce faults, and strengthen system resilience.

We manage the installation process from start to finish, ensuring new components or systems are correctly configured and ready for long-term operation. Proper installation supports consistent temperature control, stronger efficiency, and reduced operational risk. Our technicians verify performance benchmarks and help ensure smooth integration to avoid workflow disruptions.

With modern, well-matched equipment, your business benefits from fewer breakdowns, better energy usage, and improved operating predictability. Updating legacy systems often results in more dependable temperature control, easier maintenance, and stronger compliance. Our solutions are designed to help modernise your operations for future growth, allowing you to support expanding temperature control demands confidently.

As technology progresses, refrigeration and environmental control equipment becomes more efficient, stable, and precise. Upgrading older systems allows businesses to enhance performance without needing full replacement. TIESA offers targeted system upgrades designed to improve temperature accuracy, lower energy usage, and support long-term operational stability.

We evaluate your current equipment to identify areas where upgrades can deliver meaningful benefits—whether in performance, reliability, or cost-efficiency. These improvements may involve updating aging controls, improving temperature regulation components, increasing system responsiveness, enhancing airflow consistency, or optimising operational settings.

Upgrades often help businesses ensure compliance, improve monitoring, and support more advanced temperature and humidity tracking. This added visibility improves reporting accuracy and makes it easier to maintain product quality while reducing operational risk.

Our upgrades are tailored to your environment, ensuring the solutions provided address your specific challenges. Many clients choose upgrades to reduce operating costs, improve environmental management, or extend equipment lifespan. With smarter controls and improved efficiency, your system can better handle ongoing demands.

A well-executed upgrade strengthens long-term reliability, helps prevent downtime, and keeps your operations competitive. With TIESA handling your upgrade needs, your system stays strong well into the future. These enhancements support operational resilience and contribute to improved product quality, helping businesses meet strict cooling standards and protect high-value inventory.

We service a wide range of commercial and industrial refrigeration equipment, including cold rooms, chillers, freezers, and humidity-controlled environments. Our technicians are trained to troubleshoot, repair, and maintain systems used in food processing, pharmaceuticals, manufacturing, laboratories, and more. Whether you operate a large storage facility or a specialised production environment, our team offers solutions tailored to your operational needs.

Yes. We provide 24/7 emergency support to protect temperature-sensitive products and avoid expensive downtime. Our rapid-response technicians arrive ready to stabilise conditions and begin repairs immediately. This ensures critical inventory remains safe and prevents prolonged interruptions to operations.

We prioritise emergency calls and dispatch the closest available technician to minimise disruption. While response time depends on your facility location and issue severity, our goal is to arrive promptly, diagnose the cause, and restore stable temperature control as quickly as possible. Our fast action helps protect products from spoilage and facilities from operational setbacks.

If equipment frequently breaks down, uses excess energy, or struggles to maintain stable temperature or humidity, replacement may be more cost-effective. During evaluation, we consider repair history, efficiency, and long-term performance to help you decide. If repairs still offer strong value, we recommend them; otherwise, replacement can provide better reliability and savings.

Yes. System upgrades can boost performance, enhance temperature accuracy, and reduce energy consumption without replacing the entire system. These improvements may include enhanced controls, stronger sensors, optimised settings, or improved monitoring—allowing your system to better handle workload demands and extend its useful life.

Yes. Preventative maintenance helps reduce breakdowns, maintain energy efficiency, and prolong equipment lifespan. Our maintenance services include inspections, performance testing, cleaning, and adjustment to keep systems operating reliably. Regular servicing helps maintain stable temperature and humidity levels essential for product quality.

We support a variety of industries requiring controlled temperature and humidity, such as food processing, cold storage, pharmaceuticals, laboratories, supermarkets, research facilities, hospitality, and more. Each industry demands reliable, compliant

refrigeration solutions, and we tailor our approach to suit each environment’s unique needs.

Yes. We help businesses maintain compliance with industry temperature and handling standards. Proper servicing supports consistent product quality and helps businesses meet compliance expectations. Our team helps ensure your temperature-controlled systems are functioning at the level needed to satisfy regulatory guidelines.

Yes. Our technicians identify underlying causes of temperature fluctuations—from control issues and airflow blockages to sensor faults or mechanical wear. Once diagnosed, we recommend corrective action to stabilise performance and protect product quality. Continuous stability ensures your operations remain safe and predictable.

We serve customers across Australia, supporting commercial and industrial refrigeration systems. We respond to both scheduled and emergency service requests, offering support wherever critical temperature control is needed.